Coil Test and Analysis

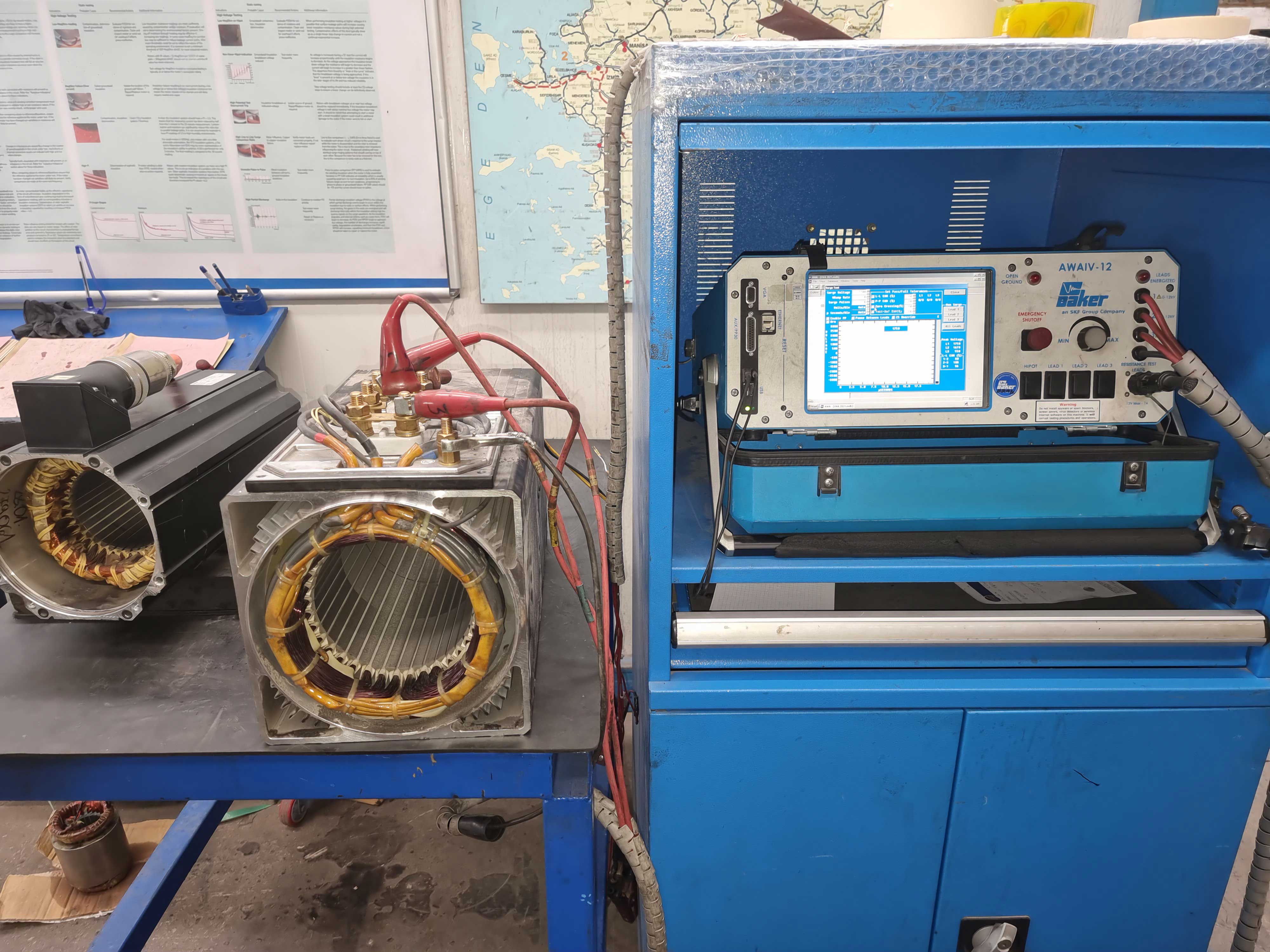

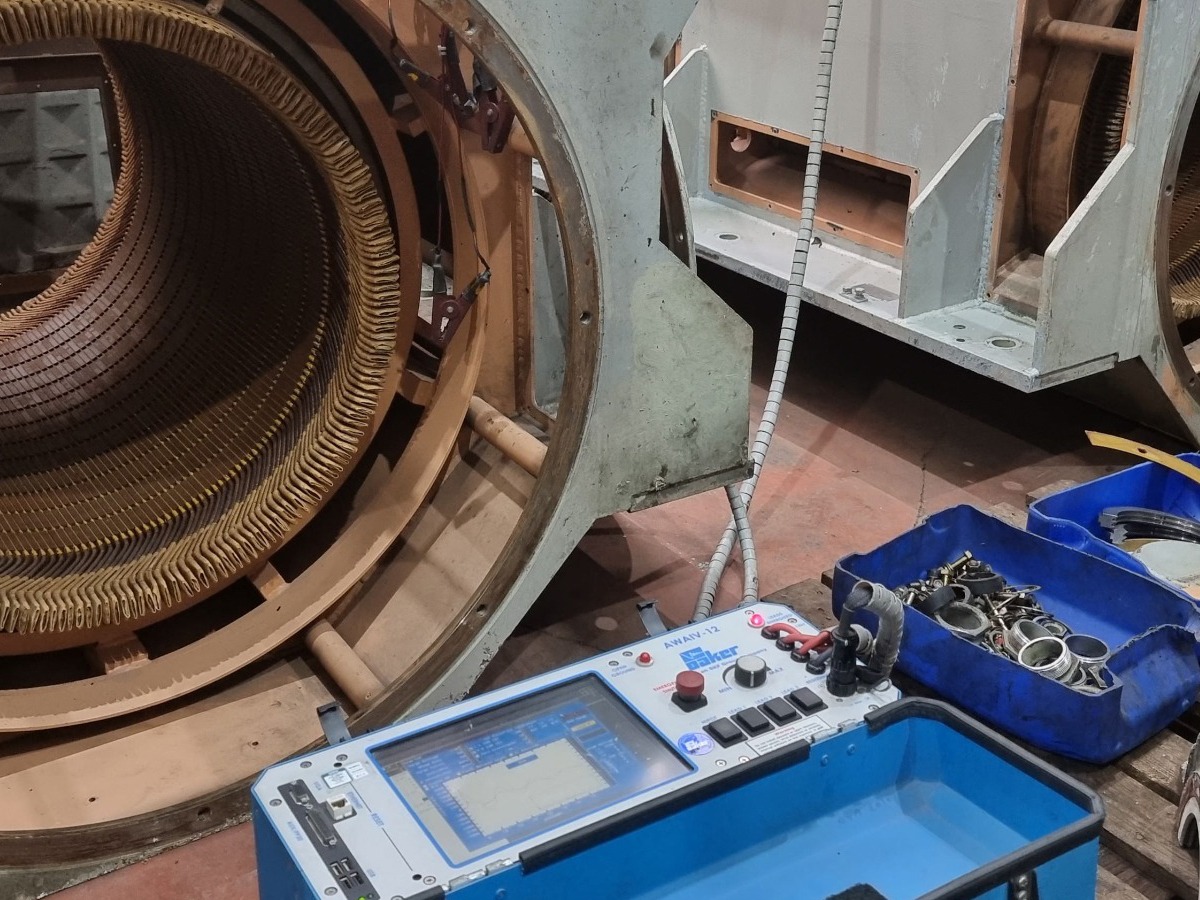

One of the important tests that determine the quality of servo motor repair and maintenance is the measurement of the insulation quality of the stator windings with respect to ground and between each other. All servo motors that come to our workshop for repair and maintenance undergo pre- and post-repair coil insulation tests to measure and record the insulation quality. The measurement of insulation quality in stator windings is crucial for the following reasons:

- To determine whether the enamel coating on the conductive copper wire has been burnt due to the heat generated during motor operation.

- To assess whether the insulation papers, which protect the phases from each other, have retained their insulation properties over time.

- To detect any damage caused by dust, dirt, oil, or other contaminants that accumulate on the coil windings.

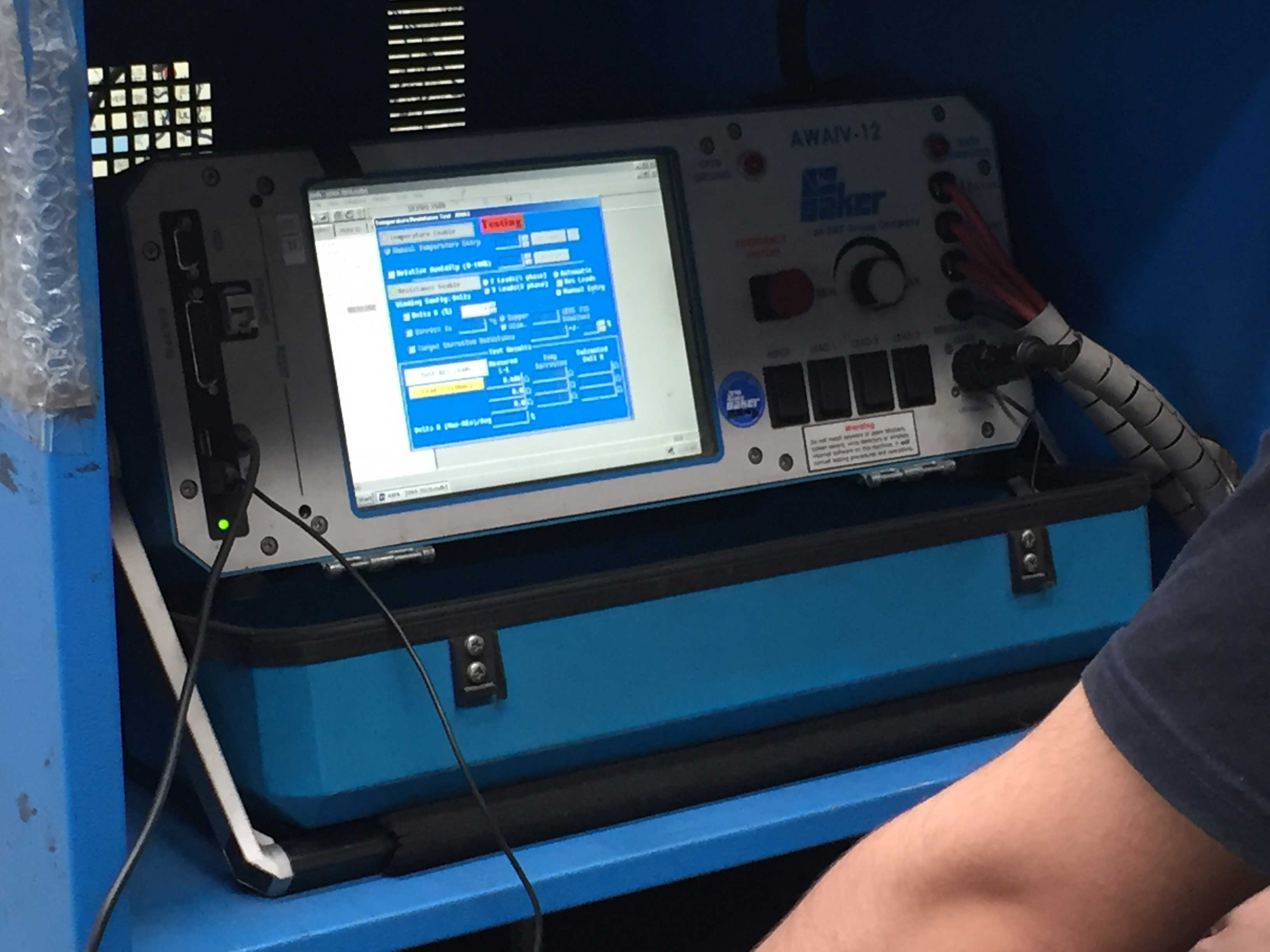

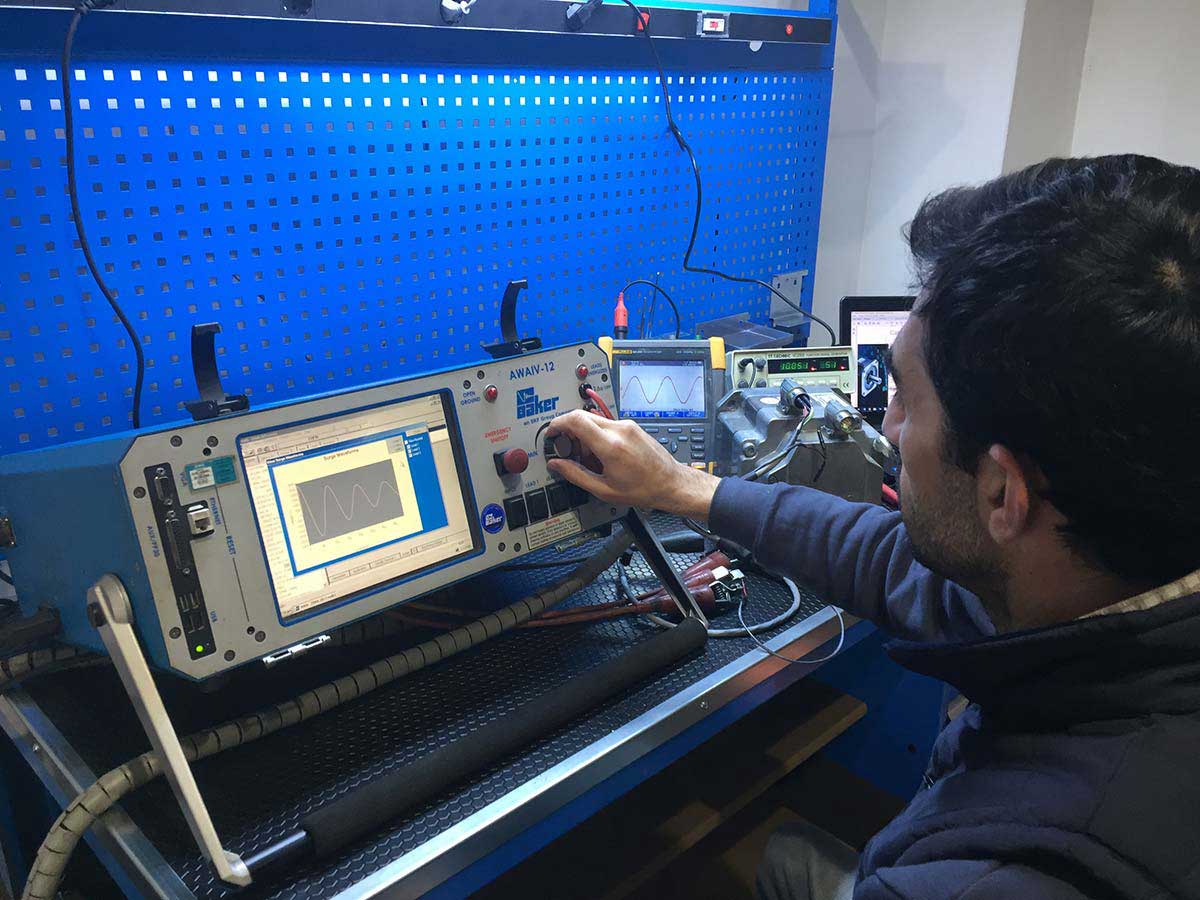

During the assessment of the insulation quality of servo motor windings, it is not sufficient to conduct a basic insulation test using an ordinary insulation testing device against ground and between coil terminals. It is essential to perform a surge test, which examines for any leakage or short circuits between the windings. This is particularly important because servo motors are generally small in size, and their windings are connected in a star configuration with three power terminals. In such cases, it is not possible to conduct inter-winding insulation tests. Our company utilizes a Baker brand HIPOT SURGE test device, which is one of the most important testing equipment in our technical infrastructure, to perform all the necessary coil tests and measurements on servo motors with high quality and reliability.