Testing and Analysis of Feedback Devices

The most significant feature that sets spindle motors apart from other motors is the presence of feedback devices, known as sensors and encoders, mounted on their shafts. In today's manufacturing, machines rely on these sensors and encoders for high precision and fast operations. These devices are not only used in spindle motors but also in various other fields such as robotics, CNC machines, and automation systems.

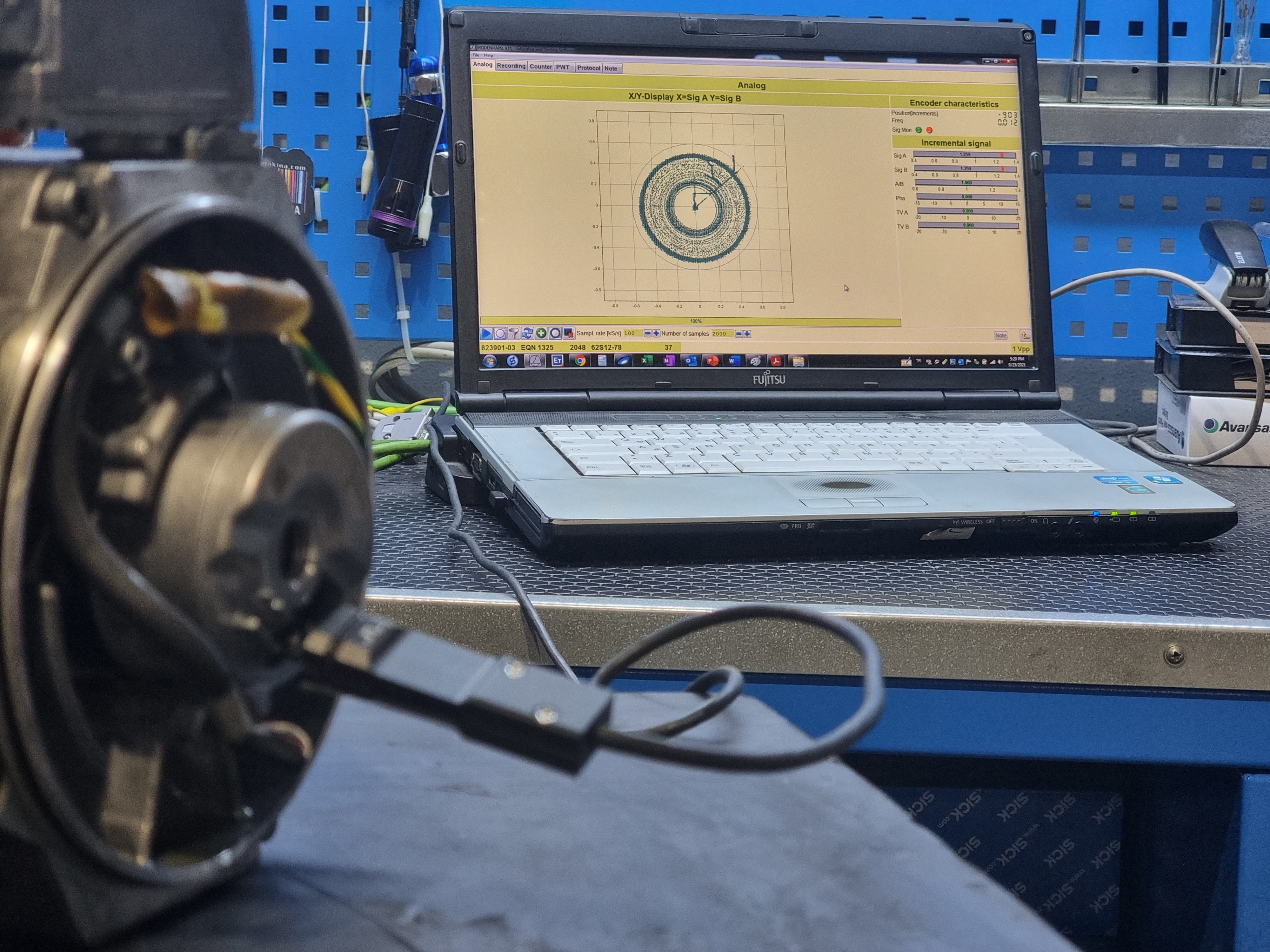

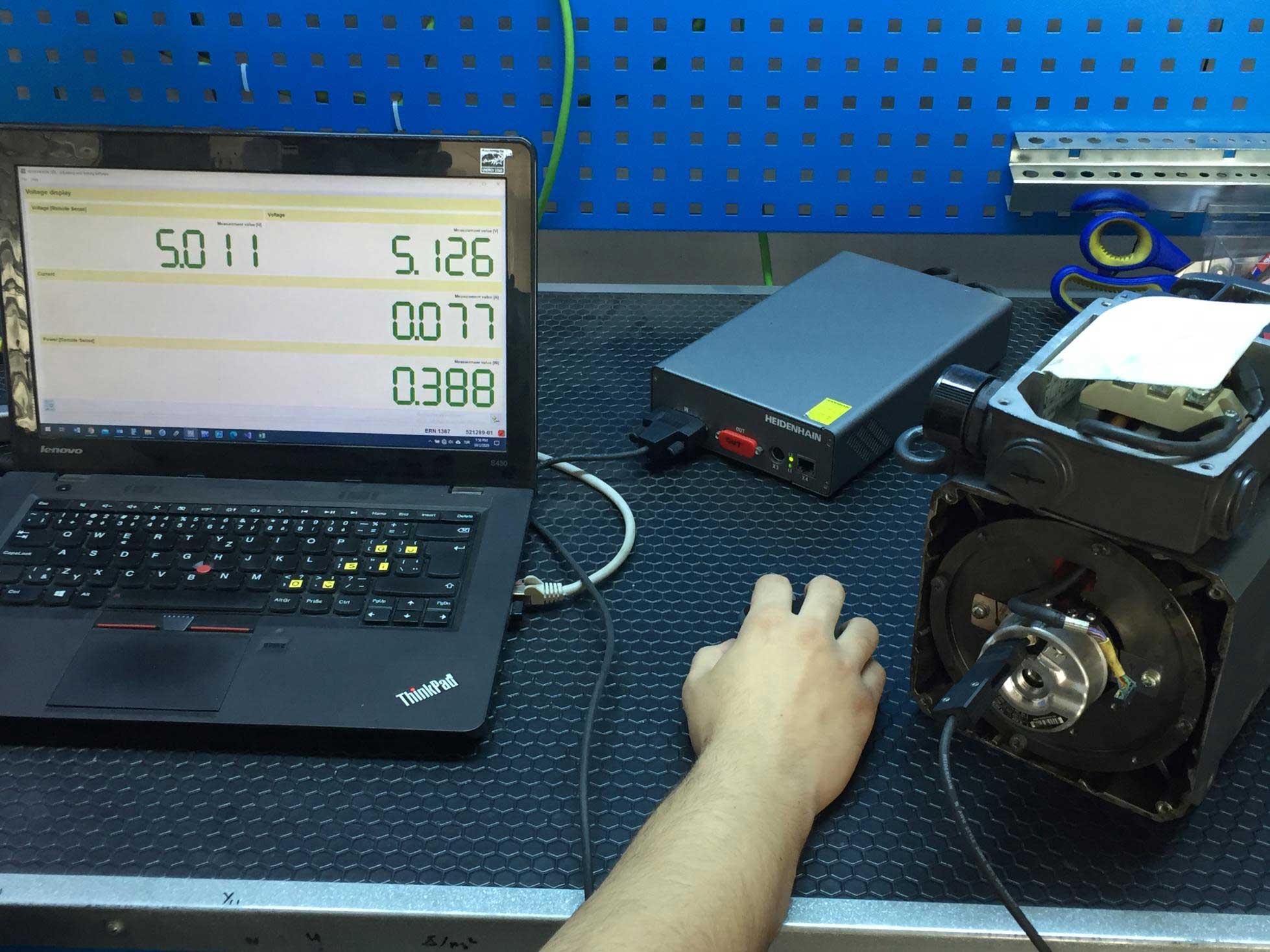

For the repair, maintenance, and servicing of spindle motors to be of high quality and successful, it is crucial to perform accurate and precise measurements and tests on the sensors and encoders. This is because the proper and smooth operation of the motor after assembly depends on the accuracy of the values obtained during the assembly of the sensors and encoders and their adjustment accordingly.

Thanks to our company's advanced technical infrastructure, we are capable of conducting tests, analysis, and calibration of renowned encoder and sensor brands with high precision and accuracy. All repaired and serviced spindle motors are tested electrically and mechanically, including the correct adjustment of encoders and spindle settings, by operating them with their original drivers before being delivered to our customers.