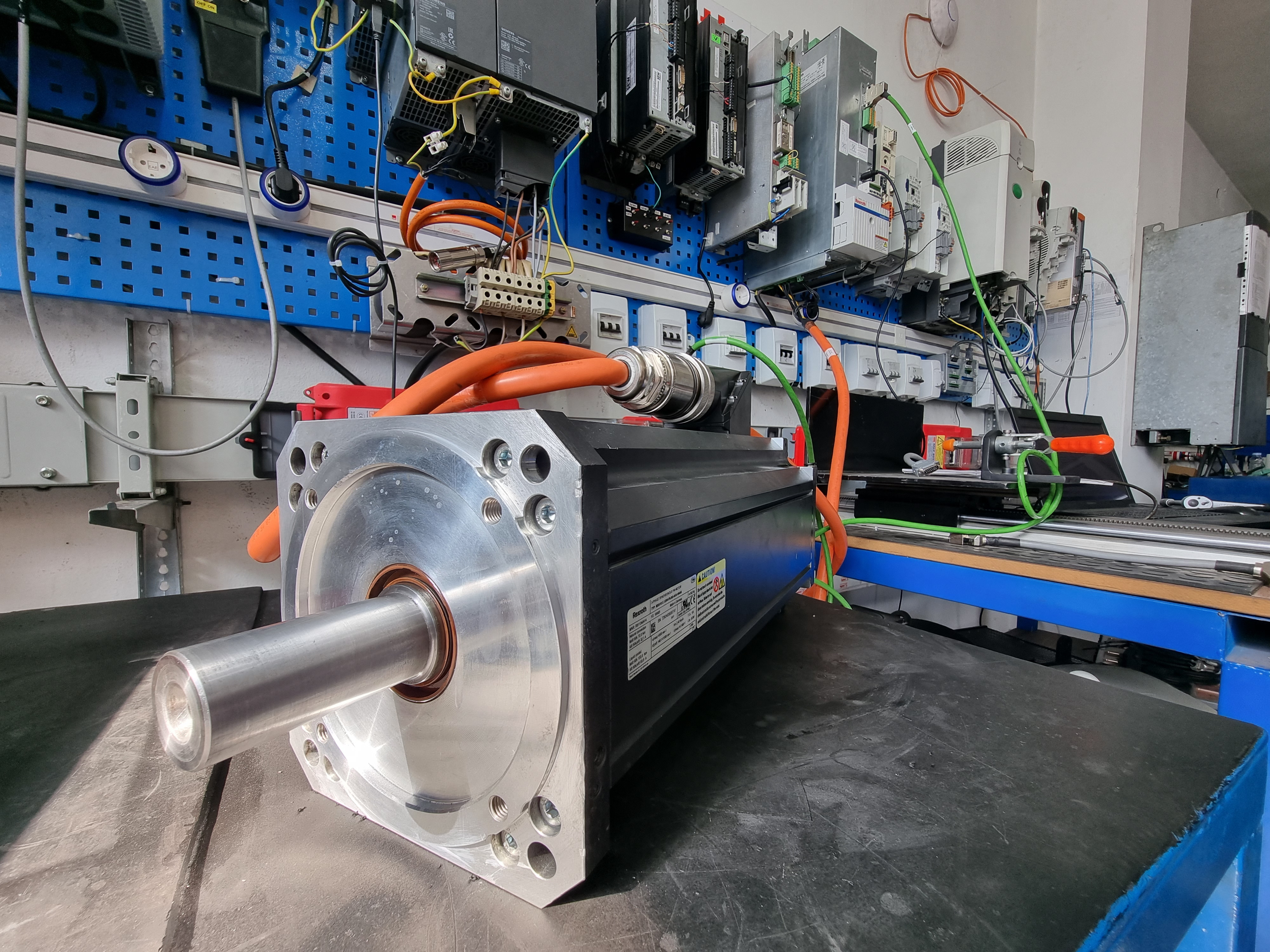

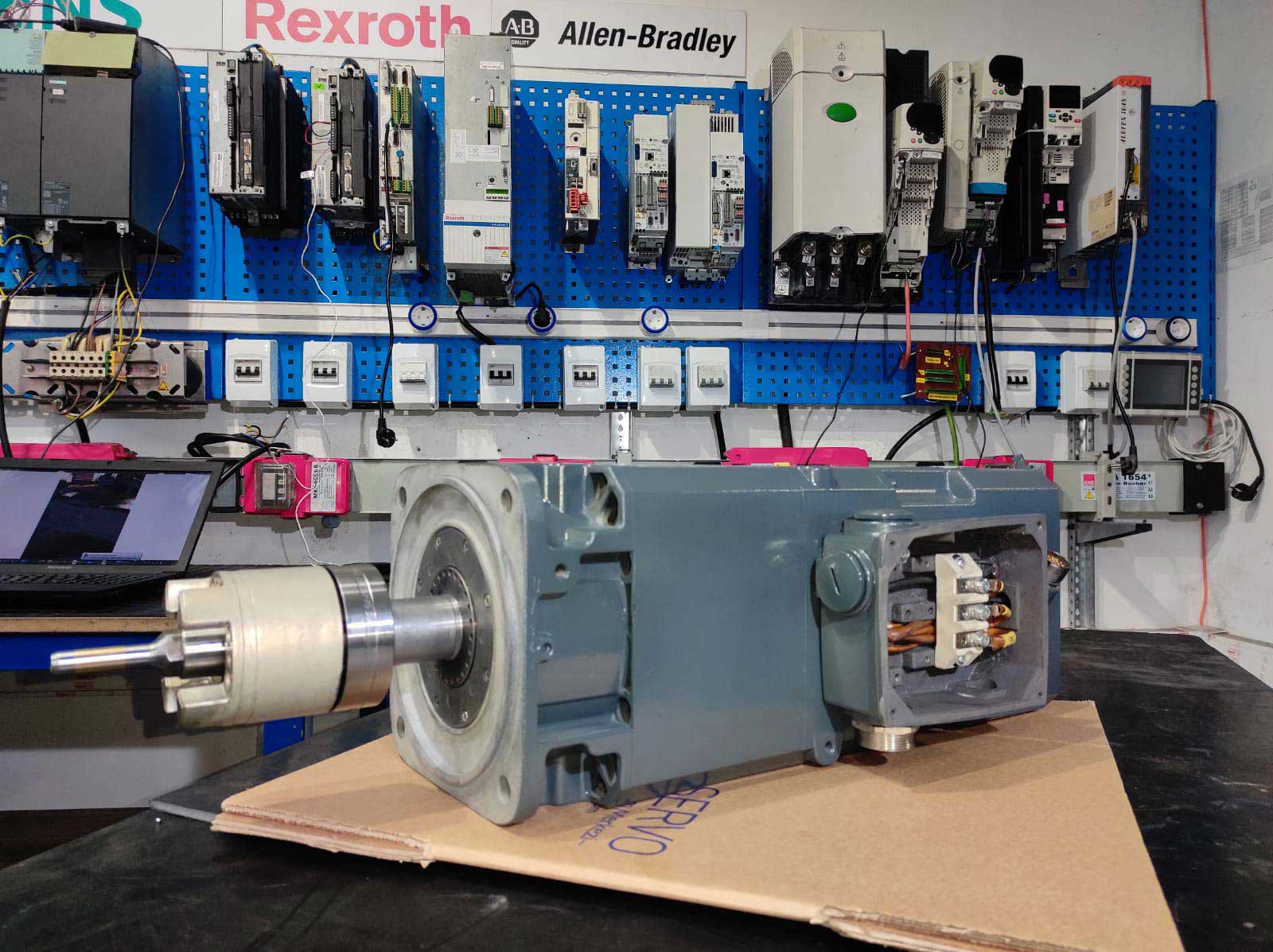

Dynamic Drive Test

We subject all serviced, maintained, and repaired spindle motors to a dynamic drive test to observe and measure their mechanical and electrical performance after maintenance and repair. The purpose of this test is to assess the accuracy and quality of the mechanical and electrical interventions carried out during the repair and maintenance stages. It is a crucial step following the completion of spindle motor repairs, including the adjustment of encoders and sensor devices to ensure their proper functioning, measurement of current and voltage values to evaluate coil quality, verification of correct stator winding if performed, measurement of thermistor values to monitor sudden changes in coil temperature and ensure accurate readings, and analysis of various details to assess the accuracy of electrical interventions. Additionally, vibration measurements of the spindle motors are conducted during this stage to evaluate the performance of replaced bearings, the accuracy and quality of mechanical interventions on the motor, and the balance of the spindle motor. These measurements are carried out using our company's balance benches and vibration analysis devices in a reliable and high-quality manner. The test and measurements are recorded in video format and shared with the customer. Motors that successfully pass the drive test are shipped to our customers, ensuring their seamless operation upon arrival.