Balance

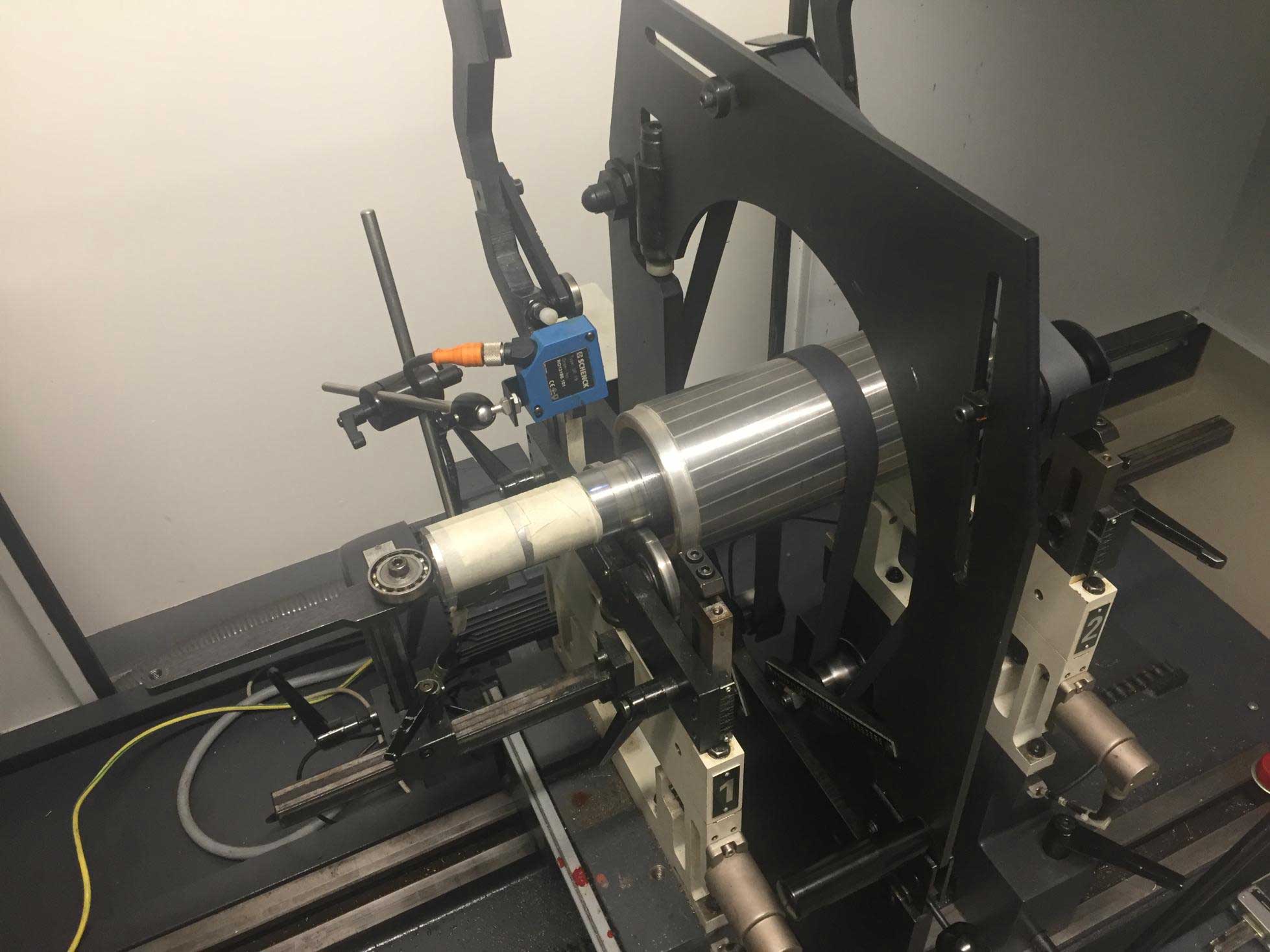

All spindle motors that undergo repair and maintenance in our facility have their rotor balances checked and inspected. The purpose of this inspection is to identify any imbalances that may occur in the rotor structure due to deformation and changes over time, and to perform necessary interventions. Imbalances resulting from high operating speeds in spindle motors can lead to damage in the bearings, as well as in the bearing seats on the rotor shaft and motor covers. If these damages are not detected in a timely manner, the disintegration of the bearings can cause the rotor to rub against the stator, resulting in damage to the windings and laminated core, increasing the repair process and costs. The rotor balances obtained using Schenck balancing machines, a leading brand in the world of balancing equipment, are highly reliable and of high quality. Furthermore, after the external balancing process, the spindle motors are assembled and subjected to dynamic drive tests. During this process, any remaining imbalance observed in the final measurements taken using our SKF CMXA 80 vibration and balancing measurement device is addressed on-site in our workshop. These tests and measurements are recorded on video and shared with our customers. Motors that successfully pass the drive tests are then sent to our customers, ensuring trouble-free operation upon their arrival.